| Processing Material : | Brass & Special Copper Alloy |

| Machining Facility : | » Brass Bar Turning & Machining on Automatic Lathe » Brass Bar CNC Machining and Turning » Brass Forging plus CNC Machining » Brass Casting + CNC Machining |

| Processing Expertise in : | » Brass Screw Machining & Turned Engineering Component » Specialized Turned Fasteners » Brass Threaded & Knurled Inserts » Brass Customized Turned Parts |

| Processing Range : | » 2 mm to 75 mm Diameter from Bar » Above 75mm Forged & Machined |

| Design Aid Software : | » AutoCAD 3D, 3D Max Studio |

| Documentation : | » Sample Stage : PPAP Level III Documents » Incoming Goods : Incoming Inspection & Material Test Report » Production Stage : In process Inspection Report » Dispatch Stage : Final Inspection Report |

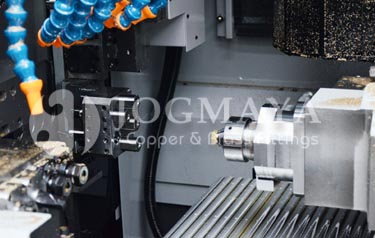

Machine Equipments

- CNC Automatic Turning Machine

- Troube Type Automatic Machine

- DTS double Cam Shaft Automatic Lathe

- Profile Drawing Machine

- 3/4 Turning Machine Automatic Troube

- Milling Machine

- Special Purpose Milling Machine

- Special Purpose Section Cutting Machine

- Special Purpose Drilling Machines

- 1/2 Drilling Machine

- Special Purpose Threading Machine

- 1/2 Threading Machine

- 1/2 Tool Grinders

- 1 1/2" Special Automatic Troube

- 1" Special Automatic Troube

- Power Press 10 Ton Capacity

- Hand Press

- Centrifugal Deburring/ Polishing Machine

Infrastructure

With the support and backing of upgraded infrastructure facility we are able to execute our orders on time with desirable convenience. Our manufacturing unit spread over an area of 6000 sq. ft is well-equipped with various automatic and semi-automatic machinery that are used in the manufacturing process to mould and carve brass components